Building a Heat Box for Resin Casting

Resin casting in the Wisconsin winters can be a challenge, to say the least. If you have ever tried resin casting in a cold-climate area, odds are you’ve felt the cold sting of uncured resin due to temperature. Building a heat box for resin casting is the solution! For resin to cure properly, it must have a constant stable temperature above 65°F, or more, depending on your resin. Whether you’re creating your own dice, recreating cosplay parts, or making something else, building a hot box for yourself can be a lifesaver when it comes to casting when temperature is a factor.

There are a few guides around the internet for how to make a hot-box in general, but the information was rather sparse, so I decided to document my journey! Specifically, I wanted a setup for resin dice casting, so I had to ensure that my enclosure could fit the Harbor Freight Pressure Pot mod that is famous in the community. I also wanted a bit of room to store my resin as well, while still fitting on my desk.

The Plan

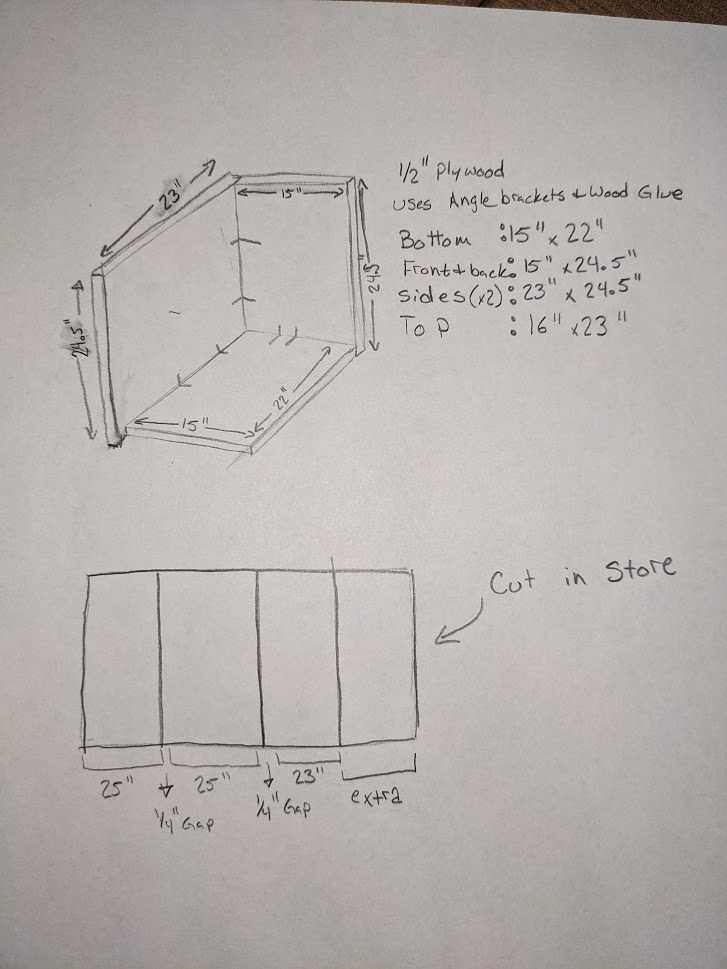

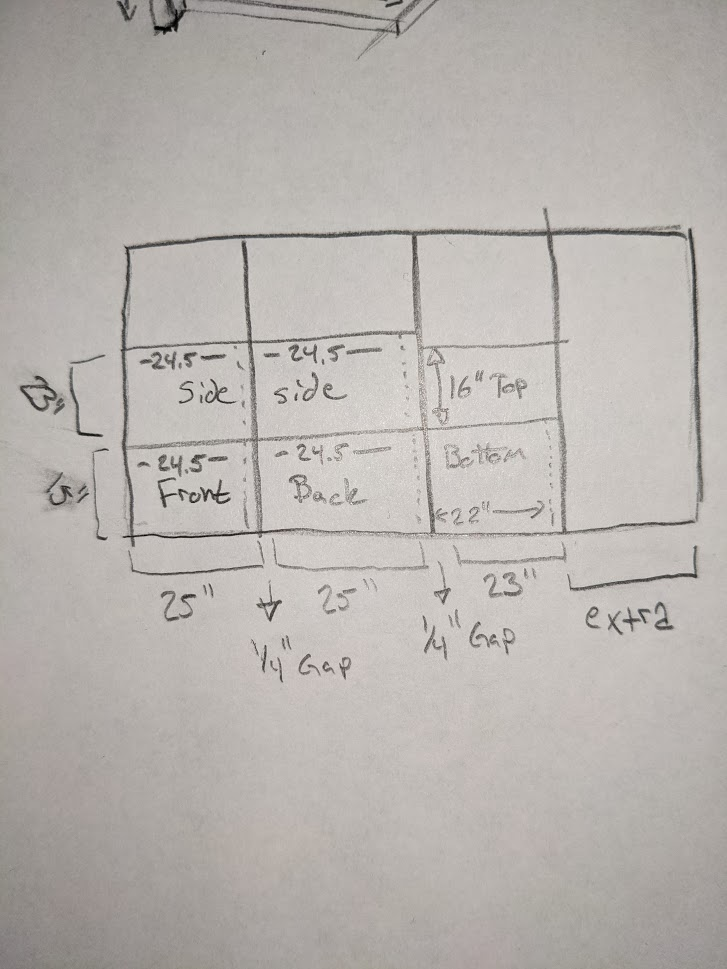

Considering these criteria, I decided I wanted the box to have the inner dimensions of 15” wide, 22” long, and 24” tall so I could easily open and close the pressure pot inside the box. As I wanted to do this on the cheap, I bought an 8’x4’ piece of ½” plywood. On sale it was a little over $20, with more than enough wood for the project. Nice! This was the plan:

In order to get this reasonably square when I got home, I gave each in store cut an extra ½ inch. Just remember if you’re marking this out that the blade will be around ¼”, so make sure you account for that gap between the cuts.

Now, carpenter’s out there: I haven’t taken a shop class since I was in middle school, so I’m sure there are much better ways of accomplishing what I’m doing here.

Materials

Hardware Store Materials

For the raw materials for the box A trip to the hardware store was in order.

- (1) 8’x4’ ½” Plywood

- (20) corner Braces, I got this in a 20 pack

- (1) 3’ 2”x4” board

- (50) ½” #6 Wood Screws

- (10) 1 ½” #6 Wood Screws

- (4) Hinges

- Wood Glue

Online Materials

In addition, I ordered a few things from Amazon that seemed to be cheaper than my local hardware store

Other Materials

There were some miscellaneous things I had around the house, like Hot Glue or some sandpaper. You’ll also need a sacrificial cable for the Light Bulb holder.

Building a Heat Box for Resin Casting

Before we get to the internals, let’s focus on the creation of the box. Per the tools I had, I set out to further divide the plywood from the store.

To make my cuts, I used the 2×4 as a straight edge with a circular saw, using a DVD case to make sure that everything was square. (It’s what I had on hand OK?) Just make sure to keep everything as square as possible when cutting. I ended up losing a ½” on the width somewhere along the line, but it still works fine.

After the pieces are cut, then it’s time for the corner braces! I laid out the boards and marked where each of the braces would go, on each board, then drilled a 3/32” pilot hole for each mark. Then, I screwed in the 10 braces on the bottom, then 4 on the front and back panels. I may have went a bit overboard here, but I had 20.

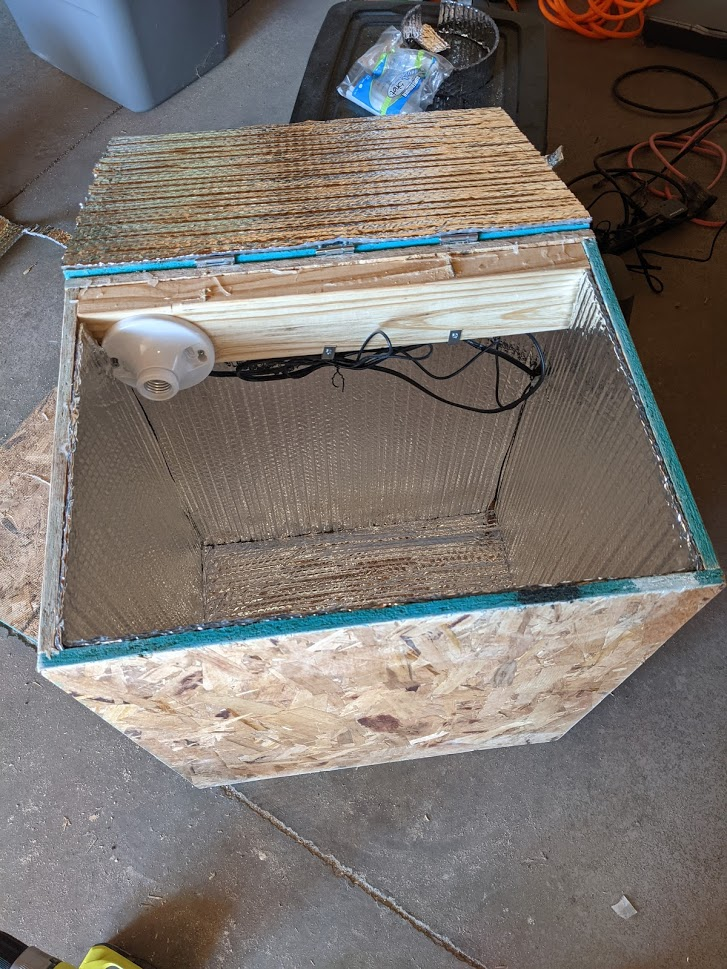

One by one, I screwed in the side panels, going clockwise. In between each of the seams, I used a generous helping of wood glue. And then it started to take shape!

I cut the 2×4 to the length of the box for added rigidity to the lid, then used the hinges to screw the lid into place. This is where the 1 ½ wood screws come into play, drilling directly into the 2×4 from the hinges on the back of the box.

Finally, I used an orbital sander to get rid of any splinters on the edges, but just a rough pass of any sandpaper should do the trick.

The Internals

Now it’s time for the Guts! The great part about having the internal height be 24 inches, is that it perfectly matches the height of our reflective insulation. Excellent! Just cut them to length. Well, except the 2×4 side. On that one, simply trim off 4 inches from the top.

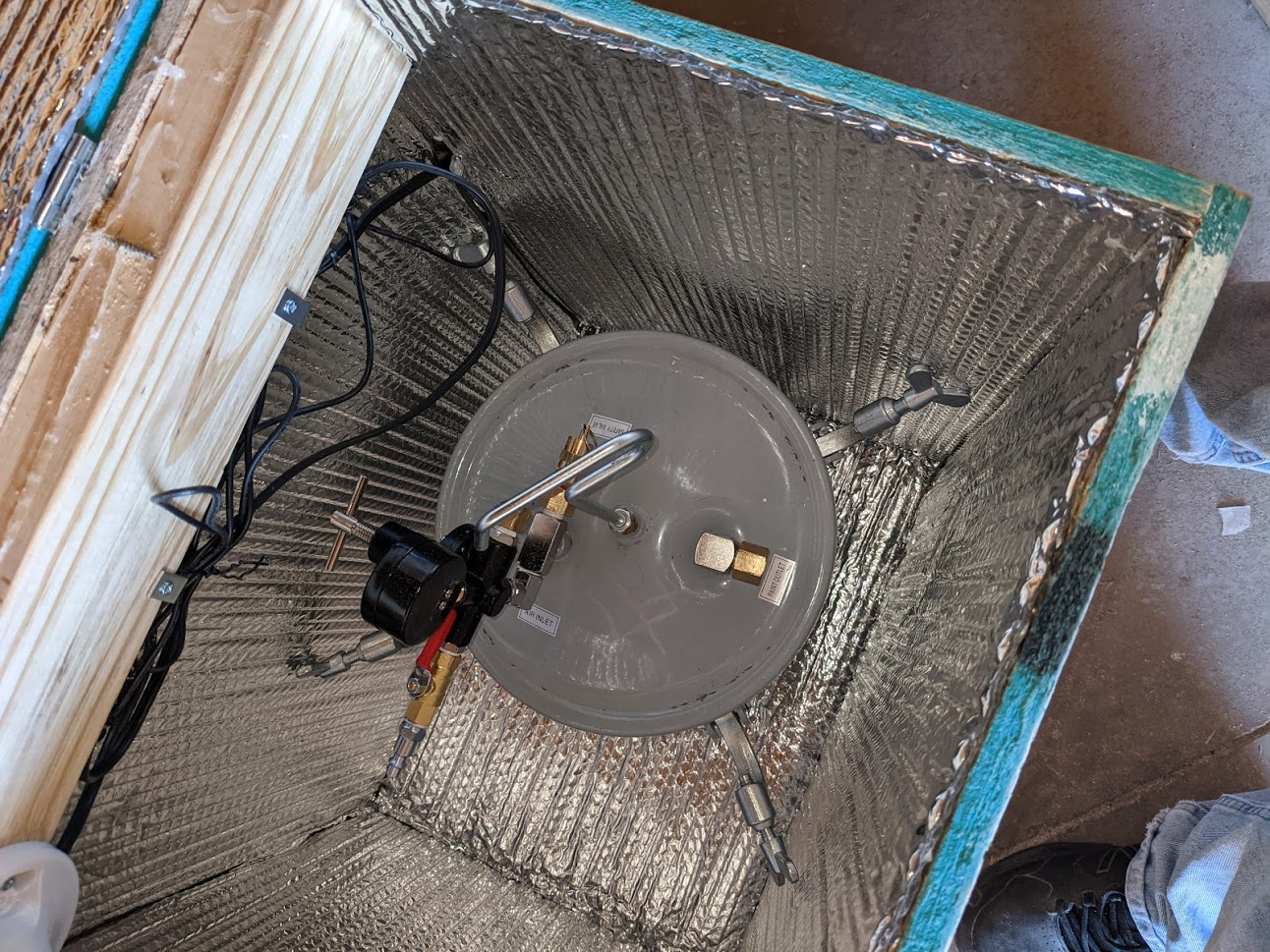

Before gluing, I mounted the temperature controller to the side, drilling a hole near a corner (away from a corner brace) for the thermometer and lightbulb cable.

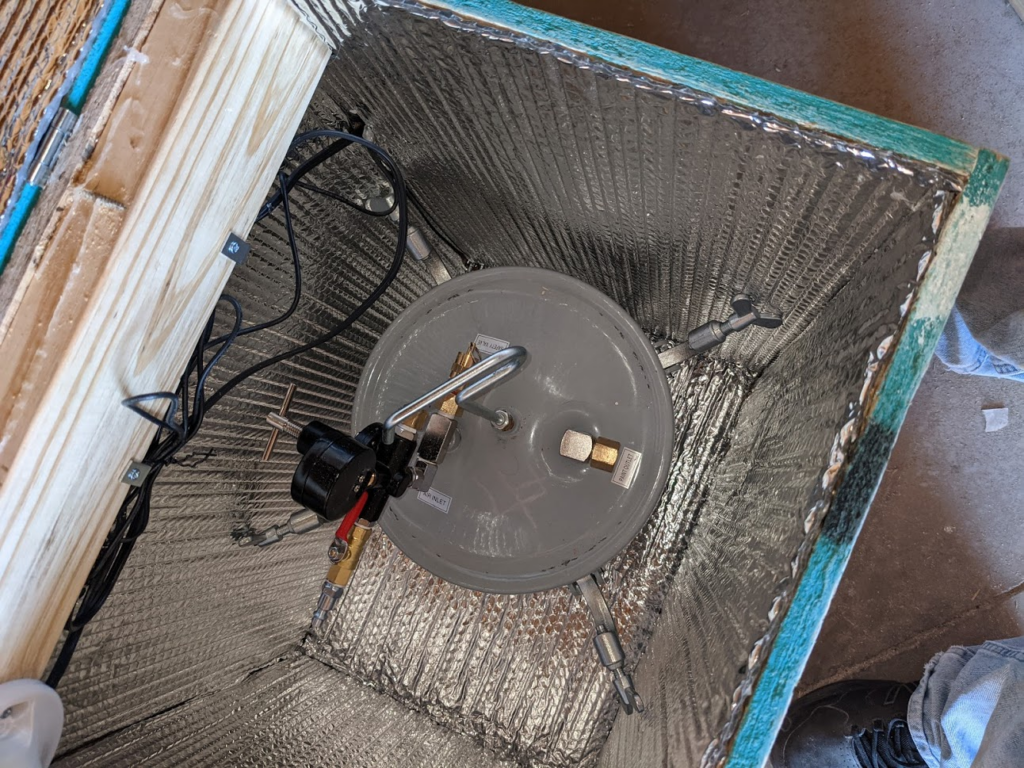

In the next flurry of steps, I cut the sacrificial cable, and attached it to the lightbulb holder, then mounted the holder to the 2×4 on the opposite side of where the pressure pot would be going. Being mindful of the cables, I glued down the insulation. Finally, I ran the thermometer cable through the trimmings of the insulation to the furthest point from the lightbulb that it could be (not pictured). I had it on the top at first, but since heat rises, there wasn’t a consistent temperature throughout the box, so I ran it to the bottom, hidden in the shade of the pressure pot.

And here it is, in all its glory!

How well does it work?

Honestly, it works amazingly well. Now I’m not storing this in sub 0 temperatures, but it get’s fairly cold where this is set up. I’ve had no trouble with freezing, and the box stays at a balmy 80 degrees fahrenheit.

Building a heat box for resin casting is a fairly inexpensive investment as well. At time of writing, all of the raw materials can be had for around $60, which you can make up pretty quickly compared to the loss of Resin when casting goes awry.